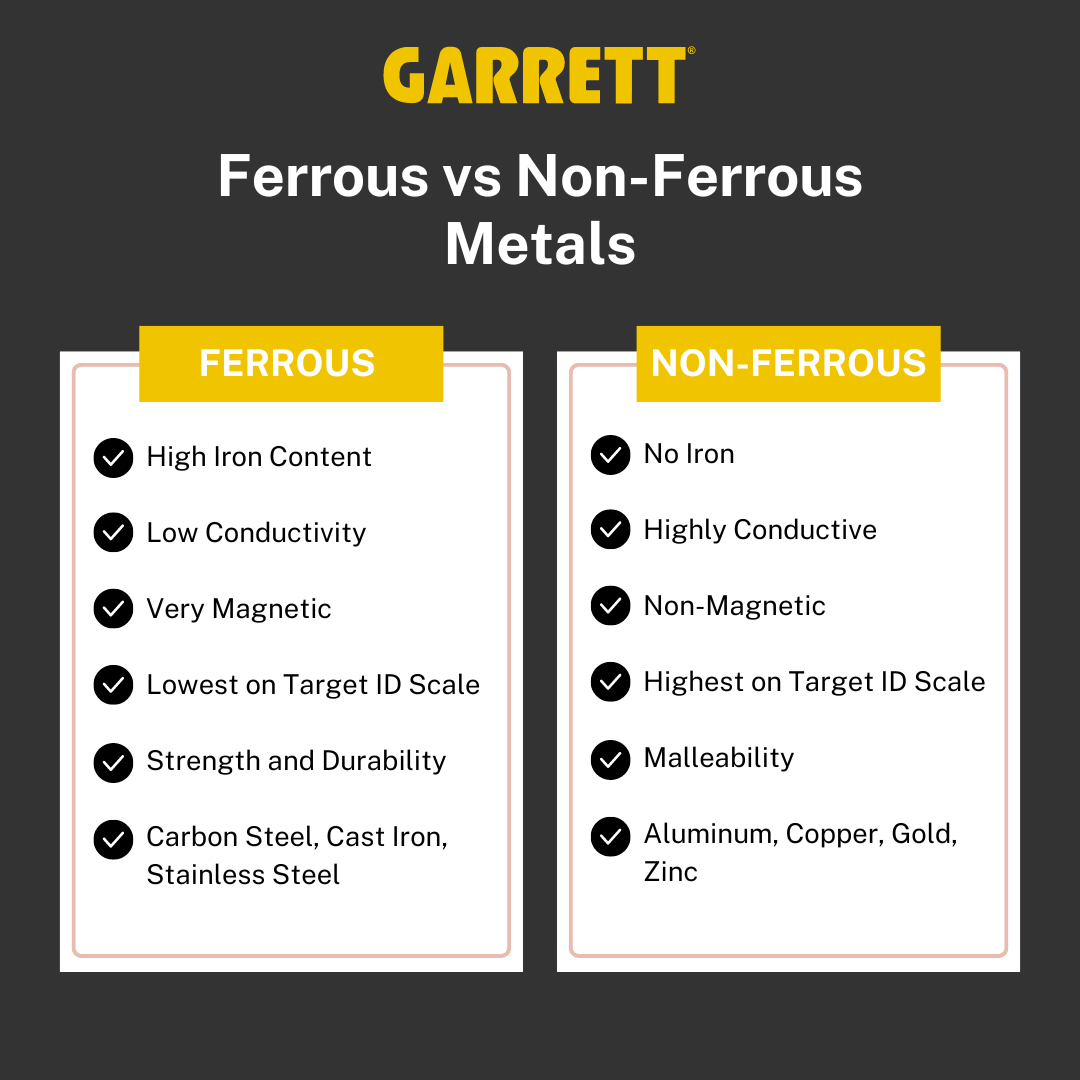

Short Answer: Ferrous metals contain iron and have a high carbon content, making them magnetic and typically more susceptible to corrosion. Non-ferrous metals don’t contain iron, are non-magnetic, and are often more resistant to corrosion.

Basic Intro to Metal Detection

Metal detectors use electromagnetic principles to detect and identify metallic objects. The process begins with the metal detector’s main components: the control box and searchcoil. These elements work together to create a magnetic field. When a detector scans an area, the searchcoil generates an electromagnetic field that passes through the space around it. Any metal objects detected in this field will transmit their own magnetic field. The searchcoil recognizes this transmitted field and alerts the user of the presence of metal through an audio signal or display. This interaction between the electromagnetic field and metal objects enables the precise detection and identification of various metals.

Electrical conductivity and permeability (magnetic characteristics) are two factors that determine how the target emits the magnetic field. The levels of these two factors play a role in how ferrous and non-ferrous metals are detected.

Defining Ferrous and Non-Ferrous Metals

To navigate the complexities of metal detection, it’s important to differentiate ferrous from non-ferrous metals.

Ferrous Metals

Ferrous metals are defined by their iron content. They have very low conductivity, are very magnetic, and show the lowest on the Target ID scale. Due to their strength and durability, they are frequently used in the construction industry. A few examples of ferrous metals you would find when metal detecting are rusty old coins, steel pipes, and nails.

- Carbon Steel: An alloy of iron and carbon that combines high tensile strength and malleability.

- Cast Iron: Known for its wear resistance and thermal conductivity.

- Stainless Steel: An alloy steel that combines iron’s durability with chromium’s rust resistance.

Non-Ferrous Metals

Non-ferrous metals don’t contain iron, have non-magnetic properties, and are the most highly conductive materials. The main advantage of these metals is their malleability, which makes them ideal for manufacturing and electrical applications. Some examples of non-ferrous metals you would find are bolts, screws, aluminum cans, and gold rings. They are ranked the highest on the Target ID scale:

- Aluminum: A lightweight and low-strength material.

- Copper: Has high electrical conductivity for use in electrical wiring and other conductors.

- Gold: A highly conductive metal with great corrosion resistance.

- Tin: A malleable metal with low tensile strength and a higher resistance to corrosion.

Stainless steel is a unique type of metal because it contains iron, making it fundamentally ferrous and magnetic. However, it resists corrosion as effectively as many non-ferrous alternatives. This is due to the presence of chromium, which, when added to iron, protects the metal from corrosion. This makes stainless steel an interesting case for metal detection, as it combines the magnetic properties of ferrous metals with the corrosion resistance of non-ferrous materials.

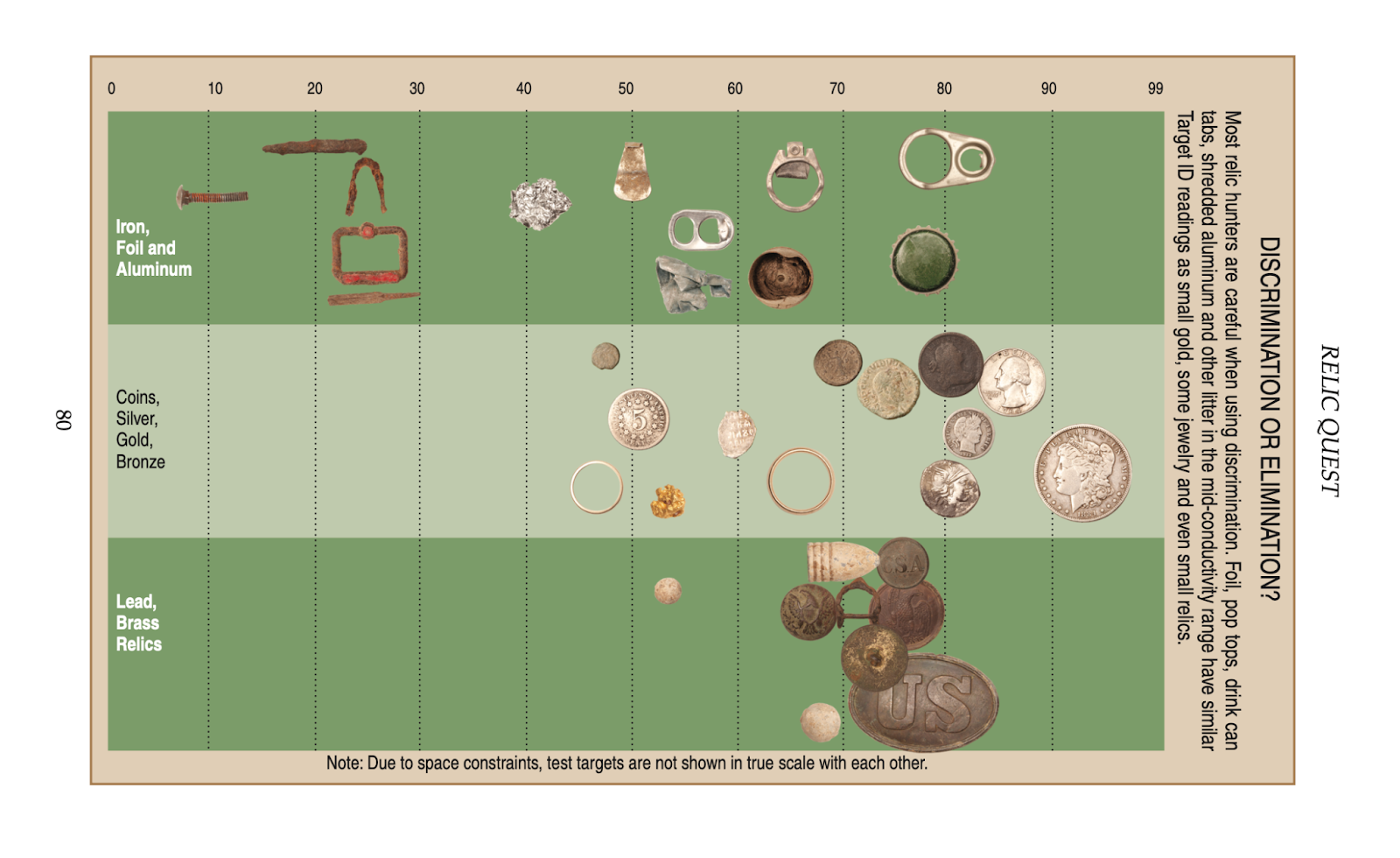

In the image above, this chart breaks down the range in which a Garrett metal detector can detect certain metals. For most Garrett detectors, they pick up ferrous targets within the 0-40 range. This may not be true for other brands of detectors, but it’s an important resource for visualizing the detector’s capabilities.

Metal Detection Techniques for Different Metals

The ability of metal detectors to distinguish between ferrous and non-ferrous metals is a testament to the innovation and intelligence of modern detection technology. This capability is essential for both security measures and hobbies.

Differentiating Between Ferrous and Non-Ferrous

As mentioned, the principle of electromagnetic induction is fundamental to metal detection. These devices emit a magnetic field that, after sensing a metal object, creates a response based on the object’s unique properties. Modern detectors are finely tuned to recognize these subtle differences, allowing for precise identification and categorization of detected metals.

Magnetic Properties and Electrical Conductivity

The detection process leans heavily on understanding a metal’s magnetic and conductive properties. For example, a change in the magnetic field’s behavior when interacting with different metals is a critical factor in identification. This allows detectors to provide more information about a detected object, enhancing the user’s ability to make educated decisions about what they’ve found.

Practical Applications: Security and Hobby

The practical applications of these detection techniques are vast.

In security contexts, being able to quickly identify the different types of metals can be crucial. A detector’s alert to a ferrous object might require a different response than an alert to a non-ferrous object, especially when assessing items that could pose a threat. Airports, courthouses, and sporting events rely on this technology to differentiate between harmless personal items and true threats. For example, being able to distinguish a steel belt buckle from a concealed weapon can streamline security checks. Similarly, in college campuses and schools, metal detectors contribute to creating a secure environment by preventing the entry of prohibited items.

For hobbyists and treasure hunters, the ability to discriminate between these types of metal allows for more targeted searching. This means focusing your efforts on areas more likely to contain valuable items like gold, coins, or artifacts, rather than areas filled with trash items. This capability increases the success rate of treasure hunts and adds to the excitement of discovering hidden treasures.

Approaches to Identifying These Metals

- Ground balancing is an important feature where you adjust and tune the metal detector to ignore its responses. Without ground balancing, it will produce extremely strong signals to the point that’s almost impossible to find a target. This adjustment is essential for improving the detection of true metallic targets in varying environmental conditions.

- Discrimination allows the detector to pick and choose which targets to focus on and which to ignore, such as iron. This capability is particularly useful in areas littered with trash because it allows the user to concentrate on more precious metals. This feature is often considered to be “required” by metal detectorists.

Challenges in Detection

Despite these technological advancements, detecting certain metals can present a challenge. The composition of a metal, its size, and its proximity to other metals can all impact a detector’s ability to accurately identify the target. For example, large iron objects may sometimes register within the range of nonferrous metals, due to their substantial size and the strong magnetic field they generate. These objects can give a higher Target ID, which can make identification more difficult because the IDs can bounce back and forth. The proximity of metal also complicates detection, as overlapping signals can challenge the detector’s discrimination capabilities.

Overcoming these challenges is an important focus regarding the development of metal detectors. As technology advances, we will continue refining the accuracy with which these devices can identify and categorize metal objects, despite the inherent challenges.

Enhancing Metal Detection with Garrett

Selecting a metal detector that perfectly aligns with your specific needs is a decision that influences the success of your metal-detecting activities. With a variety of applications, from security to hobby, it’s important to use a device that is user-friendly, precise, and reliable.

At Garrett, we pride ourselves on our deep understanding of metal detection. We design our detectors with the end user in mind, incorporating advanced features such as precise ground balancing, discrimination capabilities, and enhanced sensitivity to non-ferrous and ferrous materials. This expertise ensures that Garrett equipment offers unmatched efficiency and accuracy, improving your ability to identify and differentiate between various metals. Whether your interest lies in security, exploration, or treasure hunting, Garrett has the solution to exceed your expectations.

Check out Garrett Metal Detectors today and experience the difference that innovative metal detection technology can make. Visit our website today to find the Garrett detector that is right for you.

Resources:

- “Electromagnetic Methods: Metal Detectors.” EPA. https://www.epa.gov/environmental-geophysics/electromagnetic-methods-metal-detectors

- “Ferrous Metal.” ScienceDirect. https://www.sciencedirect.com/topics/materials-science/ferrous-metal

- Garrett. https://garrett.com/

- “Non-Ferrous Metal.” ScienceDirect. https://www.sciencedirect.com/topics/materials-science/non-ferrous-metal